The electroplating industry plays an important role in enhancing the durability, appearance, and corrosion resistance of various metal products. However, with its numerous benefits comes a significant environmental responsibility. Electroplating units generate a substantial amount of wastewater that contains heavy metals, toxic chemicals, and other pollutants. If discharged untreated, this wastewater can severely harm the environment and human health. That’s where a Sewage Treatment Plant (STP) for the electroplating industry becomes crucial.

We specialize in designing and delivering advanced, reliable, and efficient STPs tailored for the electroplating sector.

Read More : Sewage Treatment Plant For Sugar Mill Industry

Which Treatment is Used for Electroplating Wastewater and Why?

Electroplating wastewater contains high concentrations of heavy metals like chromium, nickel, copper, and zinc, along with acids, alkalis, cyanides, and organic compounds. To treat this complex mix of pollutants, a combination of physical, chemical, and biological treatment processes is used. Among these, chemical treatment is the most widely adopted and effective method for electroplating wastewater.

- Chemical Precipitation

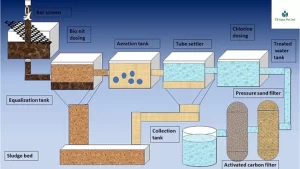

This is the primary treatment method used for removing heavy metals. Chemicals such as lime, sodium hydroxide, or sulfide compounds are added to the wastewater to change the solubility of the metals. The metals form insoluble precipitates, which can then be separated through sedimentation or filtration. This process is effective in removing up to 90–99% of heavy metal contaminants. - Neutralization

Since electroplating wastewater often has extreme pH levels (either highly acidic or alkaline), pH neutralization is essential before further treatment. It ensures optimal conditions for chemical precipitation and other downstream processes. - Filtration and Sedimentation

After precipitation, the solid particles are removed through sedimentation tanks and filtration units. This step helps in reducing turbidity and suspended solids. - Advanced Treatment (Optional)

For stringent discharge standards, tertiary treatment methods such as ion exchange, reverse osmosis, or activated carbon filtration are employed. These processes help in removing residual heavy metals and organic pollutants.

Why These Treatments?

Chemical methods are preferred because they are highly effective, cost-efficient, and suitable for treating heavy metal-laden wastewater. When combined with proper sludge handling and monitoring systems, they ensure that the treated water meets environmental discharge norms or is suitable for reuse in industrial processes.

What does electroplating wastewater mean ?

Electroplating wastewater refers to the liquid waste generated during the electroplating process, where a thin layer of metal is deposited onto a surface to improve its appearance, durability, and resistance to corrosion. This industrial process involves the use of various chemicals, metals, acids, and cleaning agents, all of which contribute to the contamination of water used during different stages like cleaning, rinsing, plating, and finishing.

The wastewater produced in electroplating units is highly polluted and contains hazardous substances such as heavy metals (chromium, cadmium, nickel, zinc, copper), cyanides, acids, alkalis, and organic compounds. These pollutants, if not properly treated, can pose serious threats to human health and the environment, contaminating soil and groundwater and harming aquatic life.

Because of its toxic nature and complex composition, electroplating wastewater cannot be released directly into municipal drains or natural water bodies. It must go through a dedicated Sewage or Effluent Treatment Plant (STP/ETP) to neutralize harmful chemicals and remove suspended and dissolved impurities.

In summary, electroplating wastewater is a byproduct of metal finishing industries that requires careful treatment and disposal to ensure regulatory compliance and environmental protection. Proper treatment also enables industries to recycle water and reduce their freshwater consumption.

Why Choose TR Aqua for Electroplating STP Solutions?

TR Aqua brings in years of experience and a strong understanding of the electroplating industry’s unique requirements. Our STP are Custom-designed to handle specific pollutants and load characteristics.

We provide Energy-efficient and easy to operate Modular and compact, saving valuable space. Installing a Sewage Treatment Plant for the electroplating industry is more than a compliance measure—it’s a strategic decision that benefits your business, community, and planet.

We’re here to guide you every step of the way—from design and installation to maintenance and optimization. With our expertise, you can ensure cleaner operations, reduced water usage, and a stronger commitment to green manufacturing.