The membrane filtration technique is used to create a variety of products. In this procedure, a liquid is sent through a membrane system that separates it into two streams. The material that cannot pass through the synthetic membrane in the filtration system, is referred to as the retentate while the feed is known as the permeate. In the world of filtration, especially in processes like reverse osmosis, ultrafiltration, and microfiltration, Transmembrane Pressure (TMP) plays a critical role in ensuring the effectiveness of the filtration system. But what exactly is TMP, and why is it so important? Let’s break it down.

Also Read Us: How Sewage Treatment Plant Work Explain via Diagram?

What is Transmembrane Pressure (TMP)

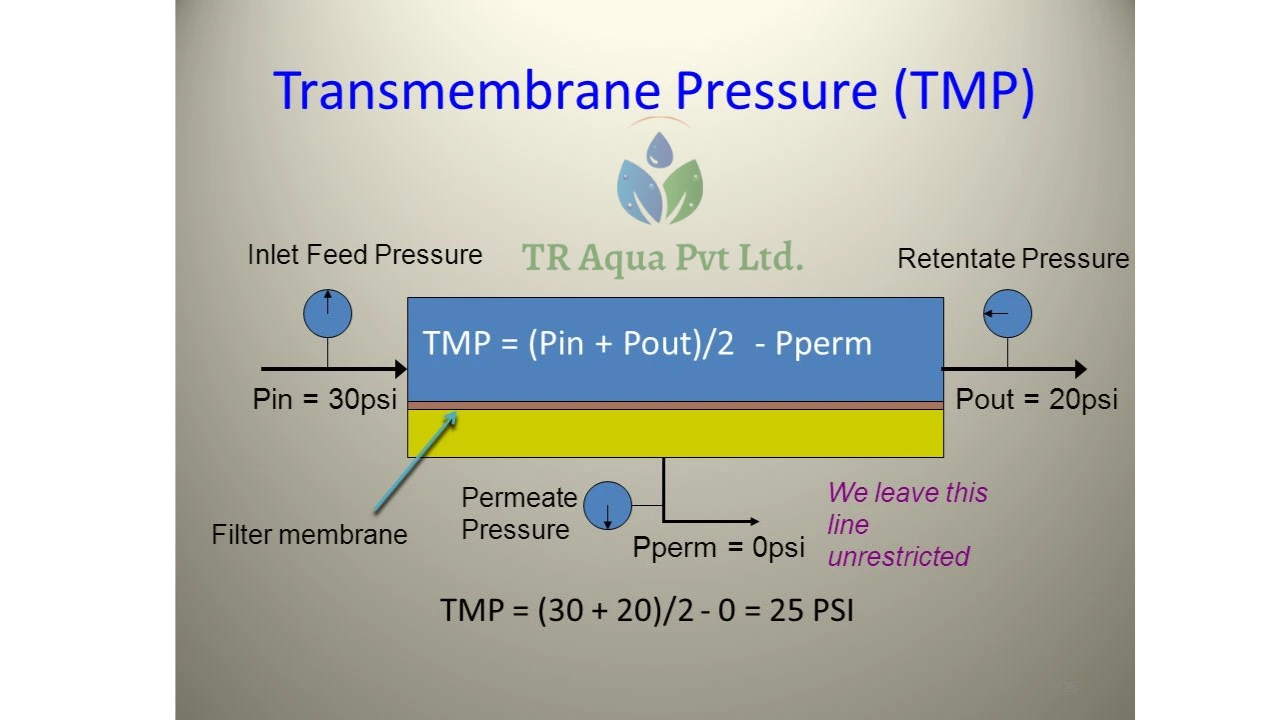

Transmembrane Pressure (TMP) refers to the pressure difference between the two sides of a membrane used in filtration processes. More specifically, it is the difference between the pressure on the feed side (the side where water or fluid enters) and the pressure on the permeate side (the side where filtered water or fluid exits). The pressure across a membrane is referred to as the transmembrane pressure. According to the material composition of each membrane, an ideal TMP exists. Crossflow filtration, however, is vulnerable to both concentration polarisation and membrane fouling, since it requires the recirculation of the feed.

Calculated Formula for TMP:

Where:

In this equation, PTMP stands for the transmembrane pressure, Pf for the input pressure of the feed stream, Pc for the pressure of the concentrate stream, and Pp for the pressure of the permeate stream. All dimensions are given in kilopascals.

The TMP value gives us an indication of how much pressure is needed to push the liquid through the membrane and how effective the filtration process is.

Why is TMP Important?

Transmembrane pressure is a key factor in the performance of membrane filtration systems. Here’s why it matters:

- Efficiency of Filtration:

- TMP directly impacts the flow rate of water through the membrane. A higher TMP typically results in a faster flow rate of filtered water (permeate). However, if TMP becomes too high, it may lead to membrane fouling or damage, which can significantly reduce the lifespan of the membrane and the efficiency of the filtration process.

- Monitoring and Maintenance:

- TMP is an important parameter to monitor. If TMP rises above normal levels, it might signal the beginning of membrane fouling or clogging, which occurs when particles, microorganisms, or other materials accumulate on the membrane surface. Regular monitoring of TMP helps detect such issues early and enables timely maintenance.

- Membrane Performance:

- Membrane manufacturers typically provide TMP guidelines that are optimal for their products. Operating within these guidelines ensures that the membrane functions efficiently without causing excessive wear and tear. High TMPs can lead to higher energy consumption, while low TMPs might indicate an underperforming system.

- Impact on Operating Costs:

- Operating a system with higher TMP might demand higher energy costs, as more pressure is required to drive the filtration process. On the other hand, maintaining TMP within recommended limits helps reduce operational costs and prolongs the life of the system.

Factors Affecting TMP

Several factors can influence the TMP during filtration:

- Feedwater Quality: Higher concentrations of suspended solids, microorganisms, or organic matter in the feedwater can increase the resistance of the membrane, raising the TMP.

- Membrane Fouling: Over time, the membrane surface can become clogged with particles, biofilm, or scaling, which increases the resistance to flow and raises TMP.

- Flow Rate: The higher the flow rate of feedwater, the more pressure is typically required to push the fluid through the membrane.

- Temperature: Higher temperatures can reduce the viscosity of the fluid, which may lower TMP, but it can also affect the membrane’s durability.

How is TMP Controlled?

To ensure the longevity and optimal performance of membrane filtration systems, controlling TMP is crucial. Here are a few ways to control TMP:

- Pre-Treatment: Using filters to remove larger particles or sediments before they reach the membrane can reduce the chances of fouling and help maintain TMP.

- Regular Cleaning: Cleaning the membrane periodically helps remove accumulated fouling material and restores its performance. Various cleaning agents and techniques, including chemical cleaning and backwashing, can be employed depending on the type of fouling.

- Adjusting Pressure: Monitoring TMP and adjusting the operating pressure can help maintain the right balance between filtration efficiency and membrane protection.

- Monitoring Systems: Installing sensors and automated systems to constantly measure TMP helps operators take timely actions when deviations from optimal levels occur.

Conclusion

Transmembrane Pressure (TMP) is a crucial parameter in filtration processes that directly affects the efficiency, performance, and longevity of membrane filtration systems. By understanding TMP, operators can monitor and control the filtration process, ensuring that membranes operate optimally, avoiding fouling, and reducing energy costs. Regular monitoring and maintenance of TMP are key to achieving long-term success in any filtration system.

At TR Aqua Pvt. Ltd., we understand the importance of TMP in membrane filtration systems and provide high-quality solutions that ensure your filtration processes operate at their best. Whether you’re dealing with water treatment or industrial filtration, our expertise and innovative solutions can help you optimize your system’s performance.